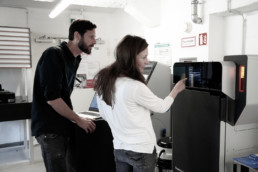

3D SLS printer Fuse1+ 30W

For high-performance parts within hours instead of days

Thanks to its high-precision results, the SLS 3D printer enables production at industrial level – with higher printing speeds and improved quality.

It is just as suitable for the production of individual parts as it is for small batches. In SLS 3D printing, nylon powder is sintered layer by layer. The unused powder supports the parts during printing, allowing complex, connected designs to be printed without the need for support structures.

Thanks to the optimized packing density and recyclability of the nylon powder, not only is a particularly stable and attractive result achieved, but virtually waste-free 3D printing is also possible, which reduces unit costs.

Installation space 165 x 165 x 300 mm

Layer thickness 110 µm

Projects with the

3D SLS printer Fuse1+ 30W

3D-printed replicas of human veins

As part of the validation fund of Kiel University, we are participating in an exciting project. Together with physicians,…

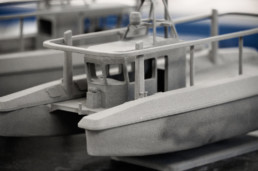

Sintered models of the “MS WAVELAB”

In cooperation with regional companies and Kiel's universities, the Clean Autonomous Public Transport Network (CAPTN) has…

Housing pressure for system control unit

Laura from "onework" has used our new Fuse1 3D printer to sinter the first housing prototypes of a system controller for building…

A laser-sintered marine sponge model

We used laser sintering to print a sea sponge that is to be used for educational projects and science communication.