High-tech meets pharmacy

Hanna, a pharmacy student on the Drug Research and Technology Master’s course at Kiel University, has developed a special device as part of her Master’s thesis: It produces powder agglomerates for high-dose inhalation.

The task was given to her as part of the work, but she had a lot of creative freedom in its implementation.

Through the intensive support of our MakerCube initiative, Hanna gained access to the latest digital manufacturing technology, including laser cutting, FDM and SLA 3D printing.

Our expert Tobi stood by her side as she optimized the device step by step – even though she had never worked with 3D printing before!

For almost half a year, she came to our home base, FabLab Kiel, every Thursday for Open Lab Day to turn her ideas into reality. The result: a successfully functioning device that overcomes the weaknesses of the old models!

We are enthusiastic about Hanna’s innovative spirit and proud to have accompanied her on her journey.

This is exactly what our MakerCube team is all about: making ideas tangible, enabling access to new technologies and promoting innovation in Schleswig-Holstein.

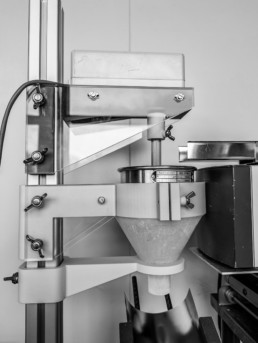

Figure 2: Part of the feeding system (the powder is automatically sieved and then falls through the hopper). Created with the laser cutter as well as FDM and SLA printing.

Figure 3: Scraper for the screen. Printed with our SLA printer after the various development stages were printed with our FDM printer to optimize the design (cheaper and easier).

The project was supervised by Prof. Dr. Regina Scherließ. She heads the Department of Pharmaceutical Technology and Biopharmacy at the Institute of Pharmacy at Kiel University.